T nuts (also known as T-slot nuts or hammer nuts) are threaded fasteners that look like the letter “T” and are designed to prevent parts from loosening and rotating during installation. It conforms to ISO, GB, ASME, DIN, JIS and other standards. It is available in diamond, square and other forms, through the slot can be quickly installed and high-strength fixed. Widely used in scenarios that require adjustable positioning.

Specifications

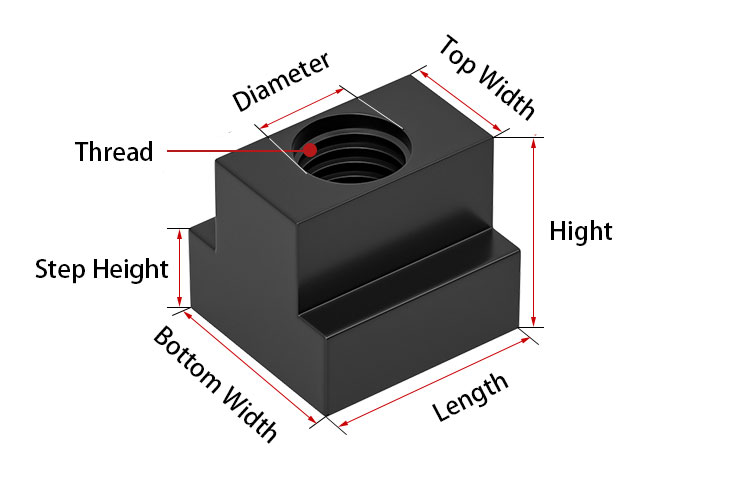

T-nut dimensions include: top width, bottom width, length, overall height, thread diameter, pitch, and step height.

- Diameter: M6 to M24 (customized)

- Threads: UNC thread, UNF thread, ISO thread, Metric thread, Imperial thread, Full thread, Half thread, Coarse thread, Fine thread

- Strength grades: 04, 05, 5, 6, 8, 10, 12

- Packing: Small Box + Carton +Pallet, Custom Packaging Service

Product Materials

- Carbon steel: Q235, Q35, 45# steel

- Stainless steel: 201, 304, 316

- Aluminum alloy: T6

- Alloy steel: 40Cr

- Brass: H62

Surface Treatments

We offer a variety of T-nut surface treatments, including: galvanized, plated, painted, anodized, blackened, Dacromet, and natively polished.

Standards

| DIN 508 | JIS B 1167 | YJT 3025 | GB/T 12868 |

| DIN 6305 | GB/T 158 | YJT 3002 | ASME/ANSI B 5.1M |

| UNI 5531 | CNS 4771 | GB /T 12868 |

Applications

- Machine Tools

- Industrial Machinery

- Construction

- Exhibits

- Furniture

- Photovoltaic Racks

Customized Manufacturing

- Non-standard size: produce special specification T-nuts according to drawings

- Surface treatment: provide various combinations of surface treatment

- Matching supply: Provide bolts, washers and other solid parts matching with T-nuts.