Self drilling screws, also known as ADS screws, are a commonly used type of threaded fastener. The tail end of the screw has a drill bit-like structure that can automatically drill holes, cut threads, and complete fastening when screwed into the material.

Drill screws are different from self-tapping screws, they are highly efficient fasteners that can be directly driven into thin metals, wood, and composite materials without the need for pre-drilling. They combine the functions of a drill bit, tap, and screw. In steel structure engineering, they achieve the lightest load and fastest cutting speed.

Specifications

| Size | Diameter #6 – #14, length 10 – 500 mm. |

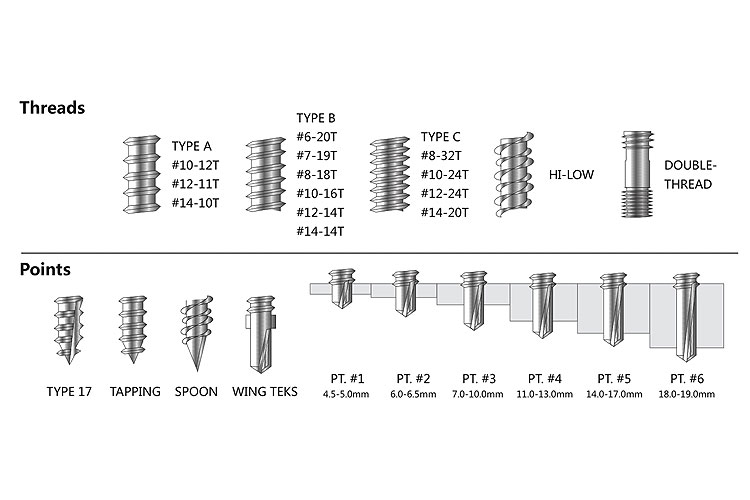

| Thread | UNC thread, UNF thread, ISO thread, Metric thread, Imperial thread, Full thread, Half thread, Coarse thread, Fine thread |

| Material | Carbon steel, stainless steel(304, 316, 410), brass, aluminum alloy |

| Strength | Grade: 4.8, 6.8, 8.8, 10.9, 12.9; A2-70, A2-80, A4-70, A4-80 |

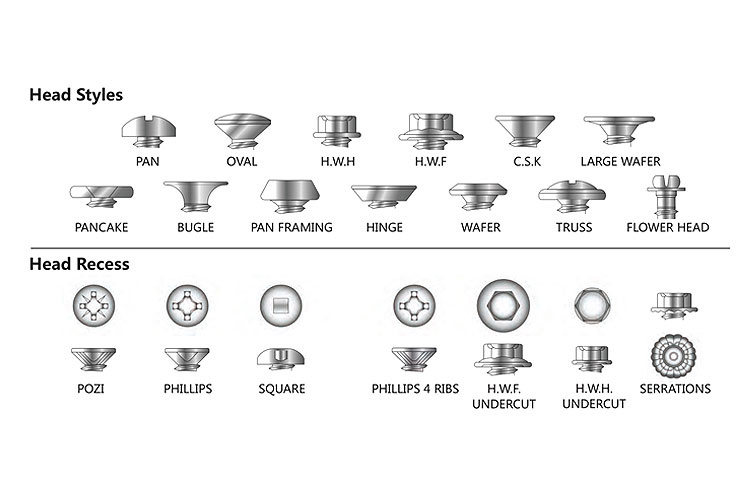

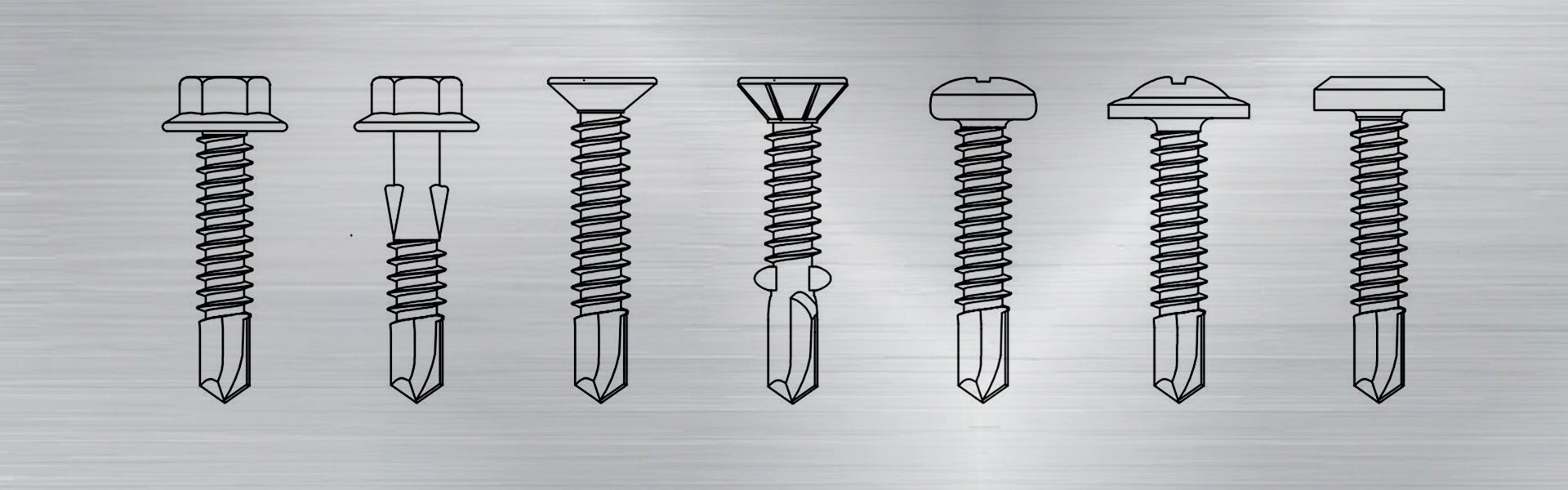

| Head Types | Hex washer head, flat countersunk, pan head, truss head, etc. |

| Standard | ISO, DIN, UNI, JIS. |

| Packaging | Plastic bag packaging, plastic box packaging, cardboard boxes, pallets or customized packaging services. |

Self Drilling Screws Manufacturer in China

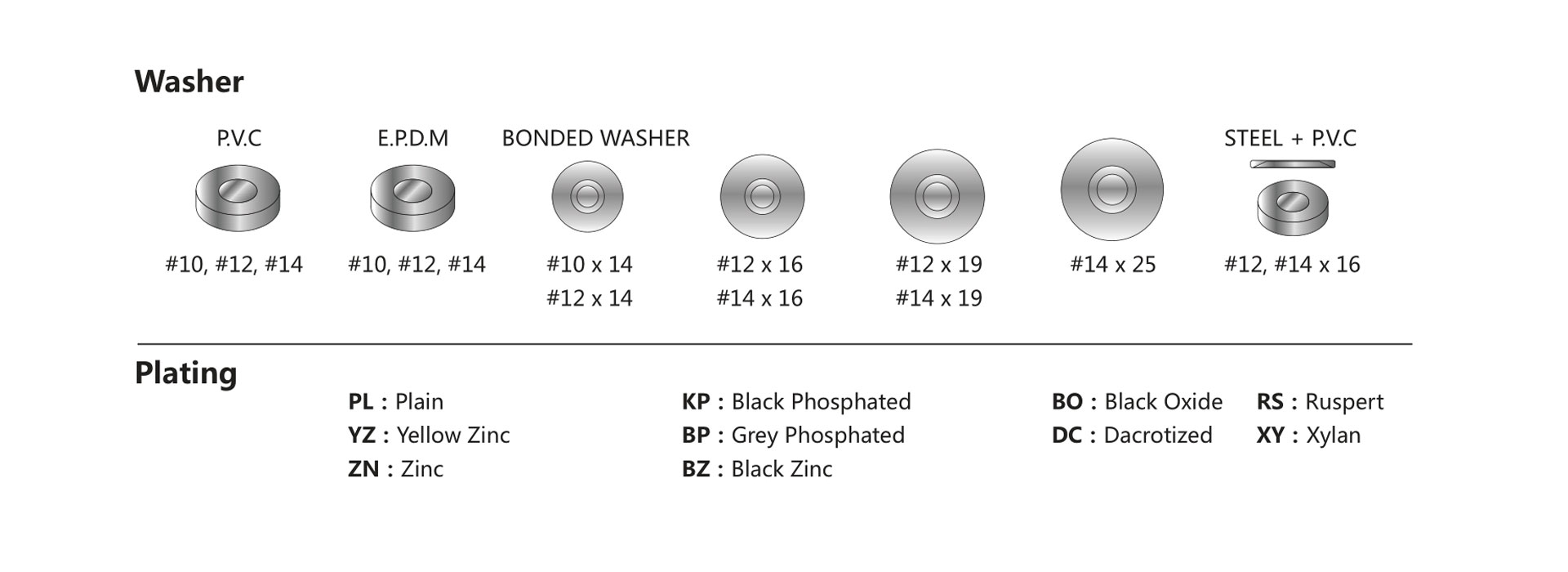

Surface Finishing

| Hot-dip Galvanizing | Black Oxide | Nickel Plating | Phosphating | Polishing | Dacromet |

| Black Zinc Plating | White Zinc Plating | Stainless Steel Passivation | Mechanical Galvanizing | Color Zinc Plating | Chrome Plating |

| Powder Sherardizing | Olive Zinc | Copper Plating | Composite Plating | Electrophoresis | Baking Paint |

| Rustban Coating | Silver Plating | Cadmium Plating | Gold Plating | Zinc-Nickel Alloy | Electroless Nickel |

| Teflon (PTFE) | Atotech | QPQ | Cleaning | Nylok (Nyseal) | Magni Coating |

| Anodizing | Adhesive Coating | Zinc-Aluminum-Magnesium | Blue Zinc Plating | Yellow Zinc Plating | Zinc-Cobalt Alloy |

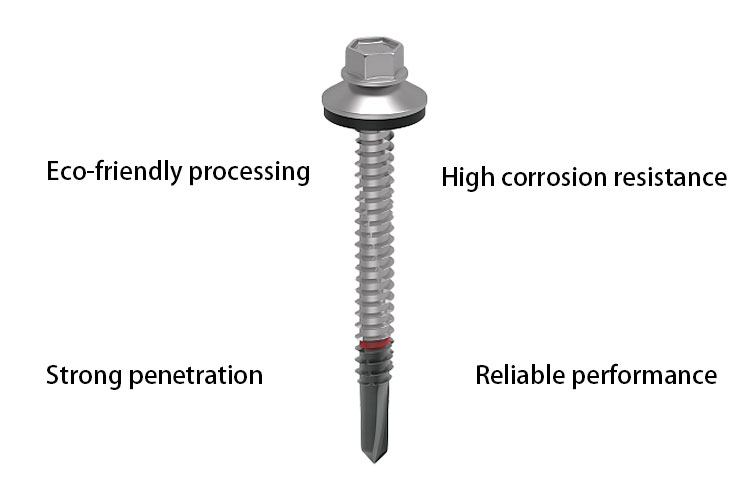

Advantages of Self-Drilling Screws from 51fasteners

Phillips Self-Drilling Screws

Phillips Pan Head Self-Drilling Screw

Standard: DIN 7504N, DIN 7504M, DIN 7516, NF E25-857, JIS B1124

- Diameter: ST3.5-ST46.3

- Length: 13-100mm

Phillips Countersunk Thread Cutting Screw

Standard: DIN 7504P, DIN 7504O, DIN 7504 R, DIN 7516DE, ISO 15482, JIS B1125, NF E25-858, UNI 8119

- Diameter: ST3.5-ST6.3

- Length: 13-100mm

Phillips Wafer Head Self-Drilling Screw

Standard: AS 3566.1-1.2

- Diameter: ST3.5-ST6.3

- Length: 13-100mm

Hex Self-Drilling Tapping Screws

Hex Washer Self-Drilling Screw

Standard: DIN 7504K, DIN 7504L, ISO 15480, NF E25-856, UNI 8117

- Diameter: ST4.2-ST6.3

- Length: 16-165mm

Hex Flange Thread Cutting Screw

Standard: GB /T 15856.4

- Diameter: ST4.2-ST6.3

- Length: 16-165mm

Torx Thread Cutting Screws

Torx Pan Head Thread Cutting Screw

Standard: QC/T 875, AS 3566.1

Torx Flat Head Thread Cutting Screw

Standard: QC/T 873, QC/T 874

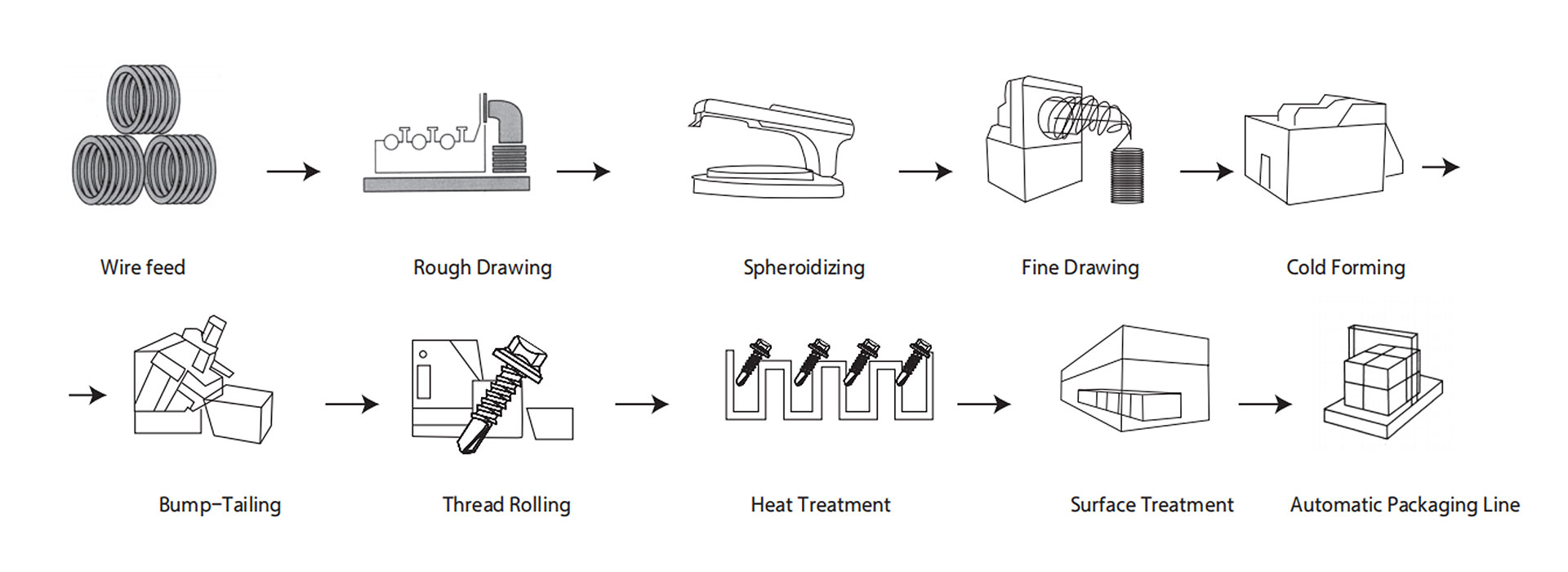

Self-Drilling & Tapping Screw Production Process

Customized Combination W/Screw & Washer

- RAL, RR or customized colors option

- Complete automatic production system

- Automatic Spray Painting Machine

- High Production Capacity

- Evenly Painted

- Obvious Head Marking

- Large Automatic Oven with Stabilized Temperature

- Customized Paint Colors (RAL and RR)

- High Quality Paint Powder

- SGS Certified

- Well-managed QC Tests

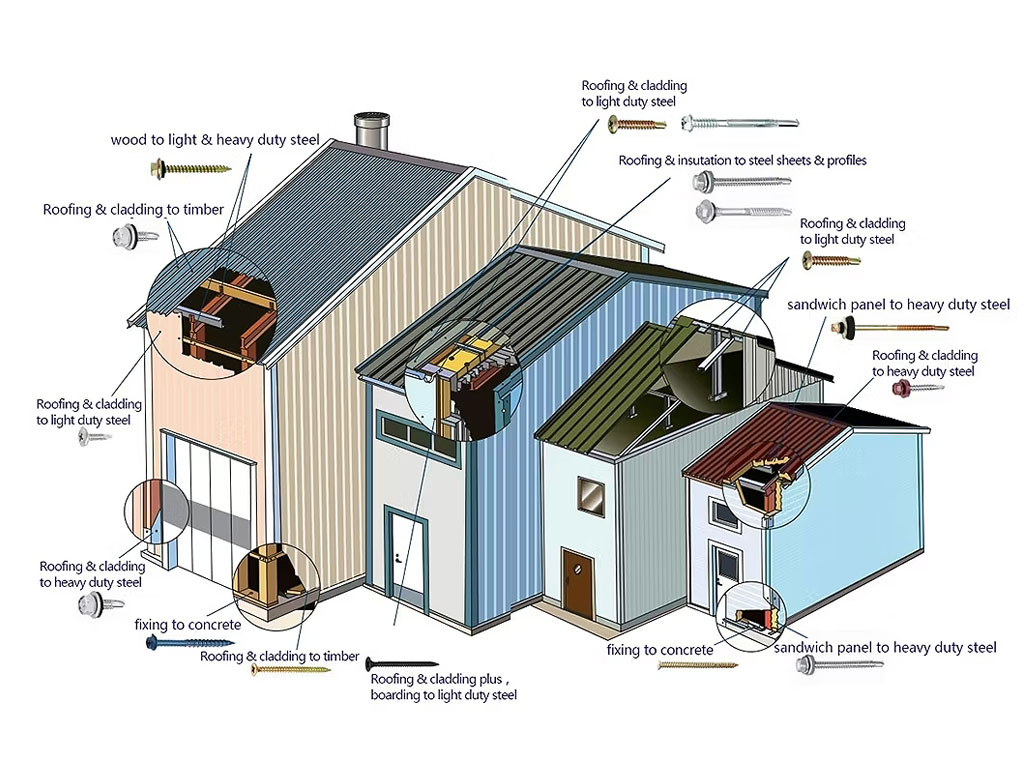

Select Self-Drilling Screws for Your Project

Self-drilling screws are widely used in metal curtain walls, metal strips, indoor and outdoor applications, steel structures, angle steel, channel steel, aviation, and many other industries.

- Construction and Steel Structures – Fixing of wall panels and ceiling panels such as light steel studs, color-coated steel sheets, resin tiles, rock wool boards, composite panels, etc.

- Automotive Manufacturing – Sheet metal parts, body assembly

- Furniture – Aluminum doors and windows, wooden structure decoration

- Livestock – Animal husbandry, aquaculture fencing and factory construction

- Mechanical Equipment – Used for securing industrial and civilian equipment components.

- Home Appliances – Used for fixing air conditioning and refrigeration equipment, smart home devices, and traditional appliances.

- Shipbuilding Industry – Decks, bulkheads, doors, ventilation systems, pipe supports, bathroom fixtures, fences, lighting systems, and signage.

Custom Self-Drilling Screws