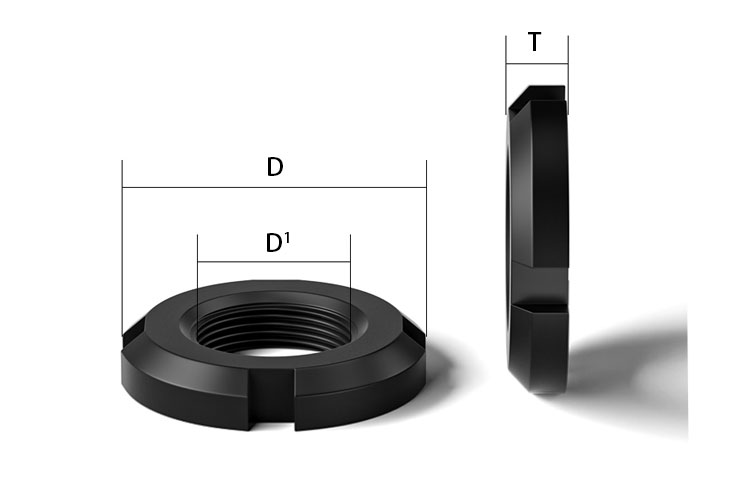

Round nuts have a rounded shape and are internally threaded fasteners with slots, radial holes, or knurled edges on the outer surface that can be used to tighten or remove the nut with a one-piece screwdriver, hook wrench, or C-wrench. Round nuts are often used in conjunction with bolts or shafts to fasten parts, and are used in narrow scenarios with high precision and low stress requirements.

- SGS professional testing

- High salt spray process

- High temperature resistance

- Acid and alkali resistant

- No color change

- Ageing resistant

- Stable surface process

Specifications

- Customizable sizes: M1 to M1600

- Customizable threads: Right-hand thread, left-hand thread, coarse thread, fine thread

- Customizable materials: A3/Q235 carbon steel, 45# steel/medium carbon steel, 30CrMo hardened, 42CrMo hardened, etc.

- Threads: UNC thread, UNF thread, ISO thread, Metric thread, Imperial thread, Full thread, Half thread, Coarse thread, Fine thread

- Strength grades: 04, 05, 5, 6, 8, 10, 12

- Packing: Small Box + Carton +Pallet, Custom Packaging Service

Materials

- Carbon Steel

- Stainless Steel

- Alloy Steel

- Titanium Alloy

- Brass

Surface Treatment

- Hot-dip galvanizing

- Oxidation blackening

- Dacromet

- Anodizing

- Electroplating colored zinc

- Natural color

What Standards Are There for Round Nuts?

| DIN 467 | DIN 547 | DIN 981 | DIN 82013 | DIN 16903-1 | DIN 16903-2 |

| DIN 1816 | DIN 546 | DIN 548 | DIN 466 | DIN 16903-3 | DIN 16903-4 |

| DIN 6303 | DIN 1804 | DIN 703 | DIN 70852 | CNS 4662-1 | CNS 4662-2 |

| CNS 4433 | CNS 4434 | CNS 4465 | CNS 4432 | CNS 4663-1 | CNS 4663-2 |

| JIS B 1119-3 | BS 4185-1-1 | BS 4185-1-2 | GB/T 817 | CNS 4664-1 | CNS 4664-2 |

| GB/T 812 | GB/T 809 | GB/T 810 | JB/ZQ 4328 | CNS 4665 | CNS 4729 |

| GB/T 9160.2-1 | GB/T 9160.2-2 | GB/T 815 | MS 3214 | MS 3359 | PN 82463 |

| GB/T 9160.2-3 | GB/T 9160.2-4 | MS 19067-1 | PN 82464 | Q391 | QJ 2392 |

| MS 19067A | GB/T 9160.2-5 |

Types

Cylindrical Nut

Slotted Round Nut

Locking Round Nut

Knurled Round Nut

Applications

- Machinery manufacturing: bearings, gears

- Electronic equipment: optical instruments, measuring equipment

- Automotive industry: gearboxes, steering systems

- Pipelines: petrochemical pipelines, water treatment equipment

- Furniture: decorative parts

- Energy: wind power generation, nuclear power equipment

- Aerospace: navigation systems, engines