Retaining rings, also known as circlip or elastic retaining ring, it is a commonly used in mechanical structure to prevent the axial movement of parts and components of the fastening elements. Retaining ring is divided into shaft and hole, the outer diameter of the hole retaining ring is slightly larger than the diameter of the assembled round hole, the installation must use the spring pliers, the jaws will be inserted into the hole of the retaining ring, clamp the retaining ring into the pre-processed round hole in the inner groove.

The retaining ring does not require additional threading or drilling, and can effectively replace the traditional shoulder, snap ring and other structures to simplify the assembly process. It is characterized by simple structure, easy installation and high reliability, and is widely used in scenarios such as bearing positioning, gear fixing and axial limitation of rotating components.

51Fasteners is committed to providing high quality and multi-specification retaining ring products to customers worldwide, supporting customization and bulk supply.

Dimensions

| Diameter Range | 3mm – 400mm |

| Thickness | 0.4mm – 10mm |

| Material | Carbon Steel, Stainless Steel, Alloy Steel, Titanium Alloy, Copper-Nickel Alloy |

| Surface Treatment | Galvanized, Black Oxide, Phosphate Coating, Dacromet, Custom Coating |

Features

✅ Easy to install

✅ High tensile strength and abrasion resistance

✅ Adaptable to high temperature, high humidity, high load and other environments

✅ Precision manufacturing, good dimensional consistency

✅ Reduced axial space occupied by components

✅ No need to process grooves, reducing production costs.

✅ Repeatable disassembly and reassembly

Retaining Ring Types

External Circlip for Shaft

The external circlip is an elastic ring-shaped fastener with a flexible small-opening structure that secures the axial position of components such as bearings and gears by stretching and locking into the shaft groove.

Standards: DIN 471, DIN 983, ASME/ANSI B18.27.1, JIS B 2804, JIS B 2807, BS 3673, UNI 7435

Internal Circlip for Bore

The internal circlip is a retaining ring used to secure mechanical components (such as bearings) inside holes. Its outer diameter is slightly larger than the hole diameter, and it is compressed into the hole groove to form an axial stop. It usually has lug holes for quick installation and removal.

Standards: DIN 472, DIN 984, ASME/ANSI B18.27.5, JIS B 2804.2, BS 3673, UNI 7437

Split Retaining Ring

Split Retaining Ring with open elasticity can be directly pressed onto the shaft of rotating components to withstand radial and centrifugal forces and prevent component loosening.

Standards: DIN 6799, ASME/ANSI B18.27.1.8, JIS B2805

Steel Wire Retaining Ring

Elastic rings made of steel wires of circular or rectangular cross-section, which are fitted into the groove and hold the part by the force of resilience.

Standards: DIN 5417, DIN 7993, DIN 9045, DIN 73130, ASME/ANSI B27.6.1, ASME/ANSI B27.6.3, JIS 2804.18, JIS 2804.19.

Rigid Retaining Ring

Non-elastic metal rings, fixed by bolts, interference fits or welding.

Standards: DIN 705, PN 85102

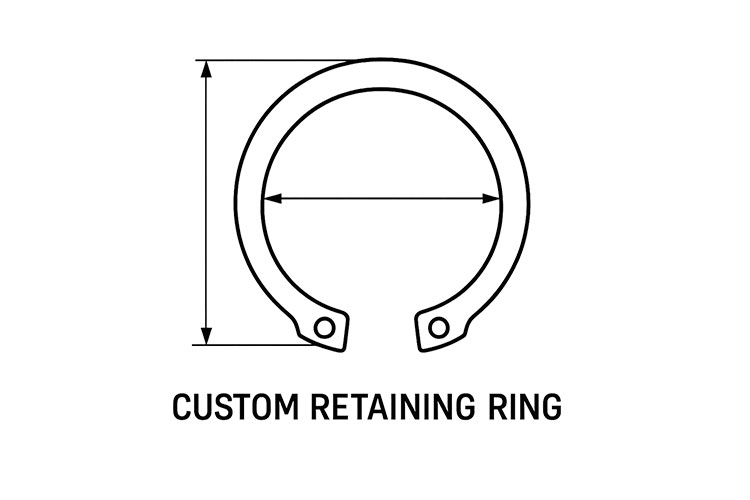

Custom Retaining Ring

Non-standard retaining rings designed for special requirements, adjustable in material, size, elasticity or structure (e.g. with seals, anti-loosening teeth, etc.)

Applications

- Automotive transmissions and drive systems

- Appliance motors and motor components

- Hydraulic and pneumatic components

- Bearing housings for industrial equipment

- Agricultural and mining equipment

Global Trusted Supplier of Retaining Rings

51Fasteners has been specializing in fasteners for more than 10 years, we provide one-stop retaining ring solutions, covering selection, customization, mass production and after-sales support. Our products have been exported to Southeast Asia, the Middle East, Europe, the Americas and other regions, serving hundreds of industrial customers, well trusted.

- Customized

- Standard retaining ring in stock

- Sturdy carton + wooden pallet for export

- One-stop solution for fastener industry

- Retaining ring manufacturer direct shipment

- CNC Finishing

- Laser Cutting

- Heat Treatment & Tempering

- Surface Treatment

- Quality Inspection

- Customized Packaging