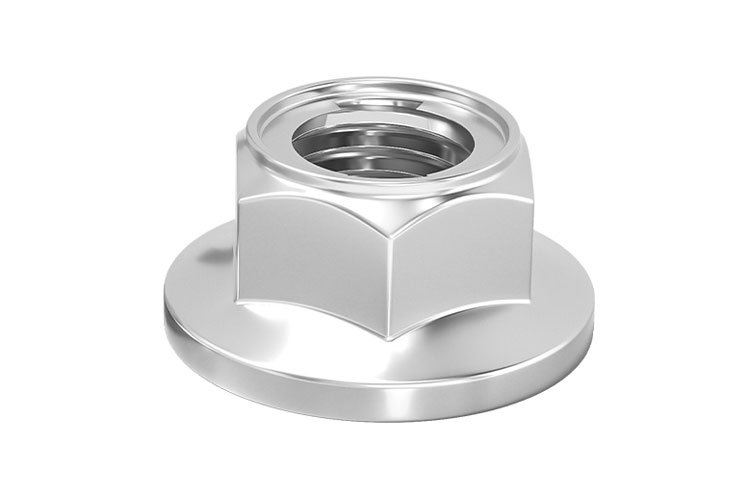

Lock nuts (also called locking nuts) have a certain elasticity compared to ordinary nuts. It is a nut designed to prevent bolts or screws from loosening under vibration, impact or dynamic loads.

Locknuts enhance locking by friction locking (nylon inserts, all-metal), and material deformation, which often require higher torque for installation and removal.

51Fasteners offers locknuts in a variety of grades, materials, standard (inch) and metric sizes.

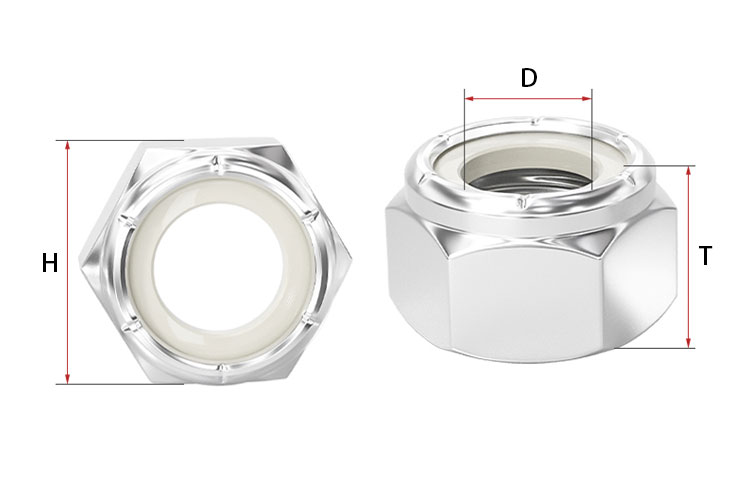

Lock Nut Specifications

- Diameter: M3 to M100

- Threads: UNC thread, UNF thread, ISO thread, Metric thread, Imperial thread, Full thread, Half thread, Coarse thread, Fine thread

- Strength grades: 04, 05, 5, 6, 8, 10, 12

- Packing: Small Box + Carton +Pallet, Custom Packaging Service

Surface Treatments

- Hot-dip galvanizing

- Electroplating colored zinc

- Oxidation blackening

- Anodizing

- Chrome plating

- Nickel plating

- Heat treatment

- Passivation

Materials

- Carbon Steel

- Stainless Steel

- Alloy Steel

- Aluminum Alloy

- Copper

- Nylon

Standards for Lock Nuts

| DIN 985 | DIN EN 1666 | UNI 8835 | GB 805 | ISO 12126 | ISO 12125 |

| DIN EN 1667 | DIN 982 | DIN 6921 | GB/T 6185 | ISO 7044 | ISO 10511 |

| DIN 7967 | DIN 6924 | DIN 6925 | IFI 100-2 | ISO 7041 | ISO 7043 |

| DIN 6927 | DIN EN 4123 | DIN 980 | GB/T 6182 | ISO 7720 | ISO 7042 |

| DIN EN 1664 | DIN EN ISO 10511 | DIN 6926 | GB/T 6183 | ISO 7040 | ISO 10512 |

| DIN EN ISO 7719 | DIN 987 | DIN 2510-5 | GB/T 6187 | ISO 7719 | BS 4929 |

| DIN 980V | DIN 980M | NF E25-409 | GB/T 889 | ASME B 18.16 | ASME B 18.16M |

| UNI 8835 | UNI 7474 | UNI 2733 | UNI 8835 | GB/T 1339 | JIS B 1199-2 |

Types of Lock Nuts

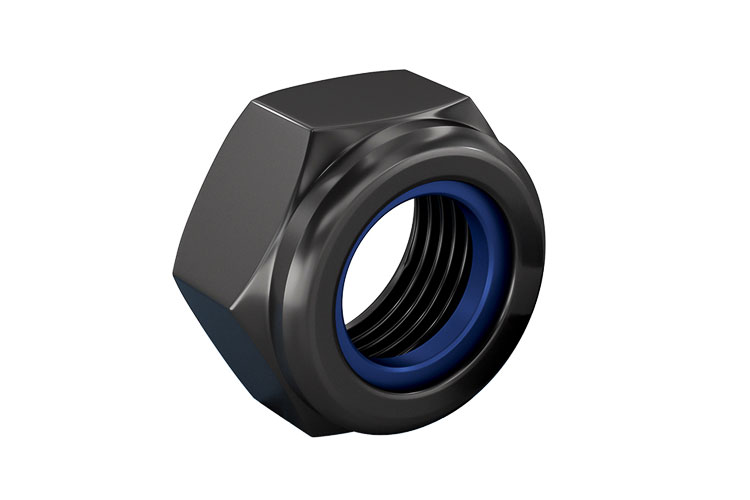

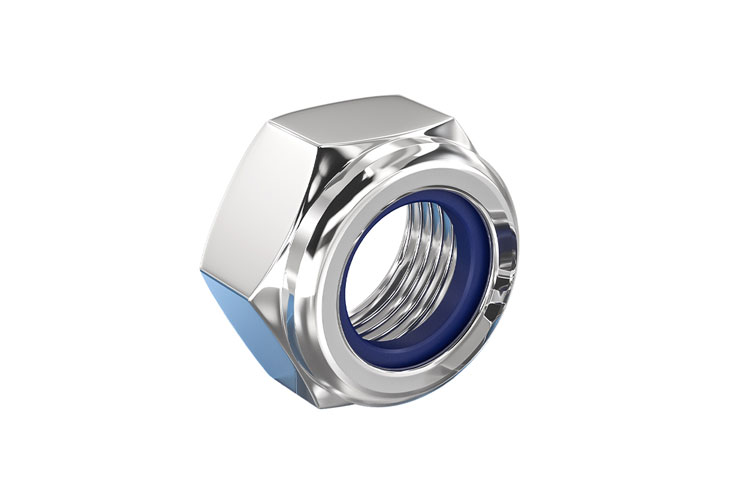

Nylon Insert Locking Hex Nuts

The top of the nut is embedded in the nylon ring, when tightening the bolt thread extrusion nylon friction, anti-loosening effect is good, the working temperature -40 ℃ to +100 ℃.

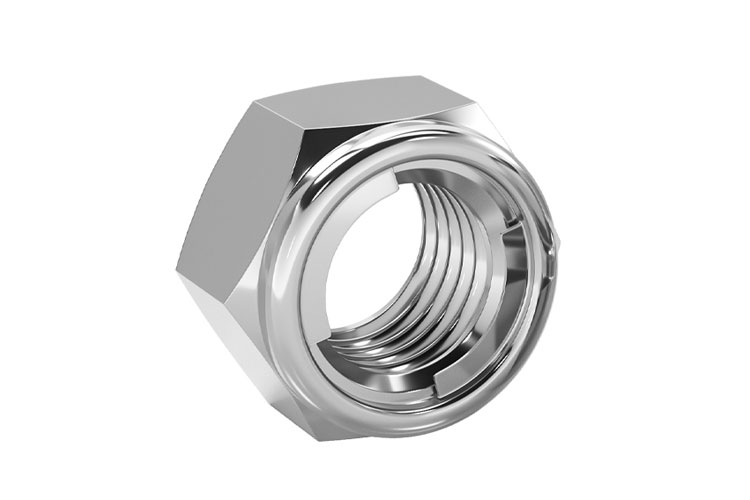

Metal Locking Hex Nuts

The upper part of the nut generates elastic clamping force by metal deformation (notching, grooving) and operates at temperatures from -50°C to +600°C.

With one-piece flange with additional non-slip teeth for increased contact surface and head with nylon insert or sheet metal locking.

Applications

- Railway Vehicle

- Construction Machinery Boom

- Wind turbines

- High Voltage Transmission Equipment

- Aerospace Components

- Ship and Port Facilities