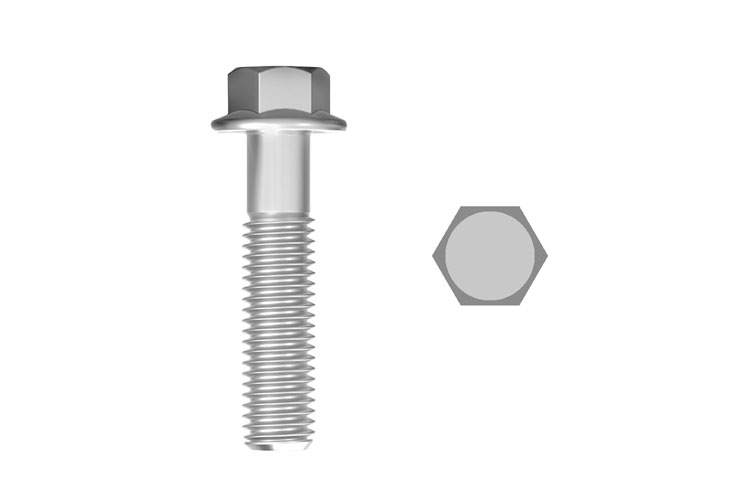

Hex flange bolts are high-strength fasteners with a hex head, flange, and shank. The flange can be large, small, flat-bottomed, or serrated (anti-slip). The flange structure increases the load-bearing area, disperses the load, reduces pressure on the connecting surface, and effectively prevents loosening, making them suitable for various high-load applications. Hex flange bolts are sometimes referred to as flange bolts or frame bolts.

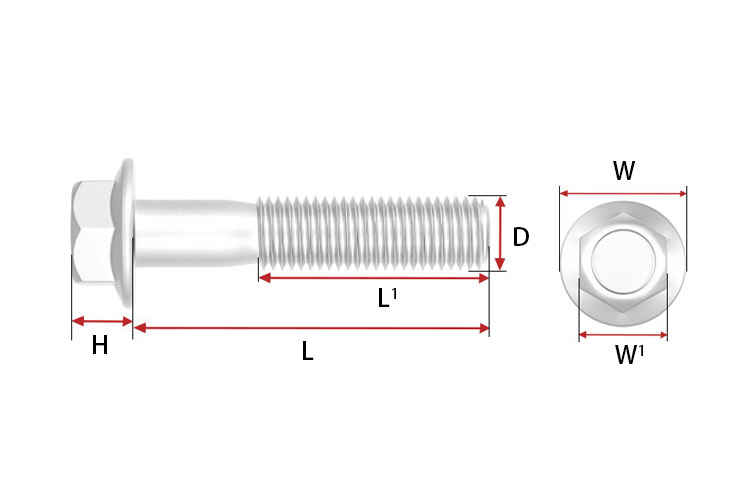

Specifications of Hex Flange Bolts

- Forming Process: Hot forging, Cold heading.

- Metric Sizes: M10 to M100.

- Imperial Sizes: 3/8″ to 8″.

- Thread Types: Metric coarse thread, Fine thread.

- Strength: Grade 4.6,6.8,8.8,10.9,12.9; A2-70, A2-80, A4-70, A4-80.

- Standard: DIN, ISO, ASME, JIS.

- Packaging: Plastic bags, plastic boxes, cartons, trays or customized packaging services.

Hex Flange Bolt Materials

- Carbon Steel

- Stainless Steel

- Alloy Steel

- Titanium Alloy

- Aluminum Alloy

- Brass

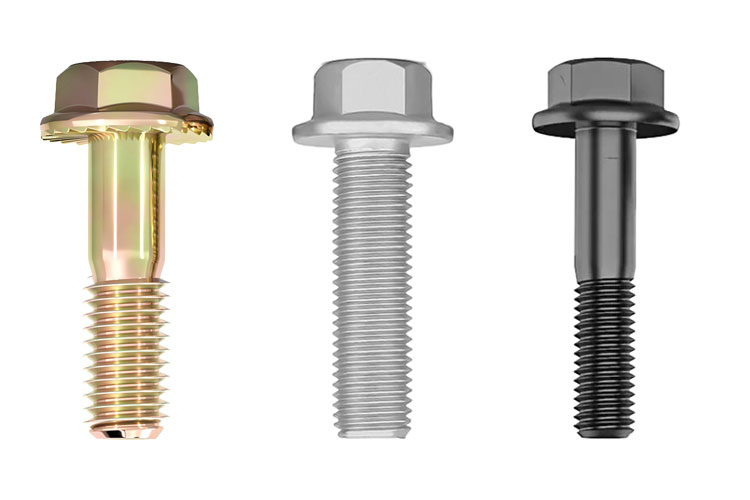

Surface Treatments for Hex Flange Bolts

- Hot-Dip Galvanizing

- Electroplated Zinc

- Dacromet Coating

- Black Oxide

- Heat Treatment

- Phosphate Coating

- Nickel Plating

World Standard for Hex Flange Bolts

| ISO 15072 | ASME/ANSI B18.2.3.9M | JIS B 1189 | DIN 6921 |

| ISO 15071 | ASME/ANSI B18.2.1-8 | EN 14219 | DIN 6922 |

| ISO 4162 | ASME/ANSI B18.2.3-32 | IFI 111 | DIN EN 1665 |

| GOST R50274 | GOST R55739 | NF E25-504 | ASME/ANSI B18.2.3.4M |

Types of Hex Flange Bolts

Flange Hex Bolts for Automobile

Brass Flange Bolt

Carbon Steel Flange Bolt

Dacromet Flange Bolt

Applications

- Automotive Industry: Trucks, heavy-duty vehicles

- Construction Engineering: Steel structures, bridges

- Heavy Machinery: Excavators, cranes

- Railway: Rail tracks

Processing Services

- OEM/ODM

- Custom Dimensions

- Surface Treatments

- Special Coatings

- Special Materials

- Mass Production