Dowel pins are high-precision cylindrical fasteners used primarily for precise positioning, fixing, or centering between two or more components. They do not rely on threaded connections, but are inserted into holes through interference fits, transition fits, and clearance fits. They are made of metal, plastic, or wood. Dowel pins are often used in conjunction with screws. They absorb shear loads and increase connection strength.

51fasteners is a one-stop supplier of cylindrical dowel pins. We offer standard metric and imperial fasteners, including bolts, screws, nuts, washers, and more. We also support custom fasteners in various materials and sizes. If you’re looking for a reliable fastener exporter, please contact us.

Features of Cylindrical Dowel Pins

- Flat and smooth surface

- Tolerance accuracy 0 to -0.02

- With chamfered or rounded ends.

- Not easily deformed

- Precise dimensions

- No burrs

- High-quality workmanship

- Sturdy and durable

- Corrosion resistant

- Rust resistant

- Excellent material

- Complete specifications

- Eco-friendly

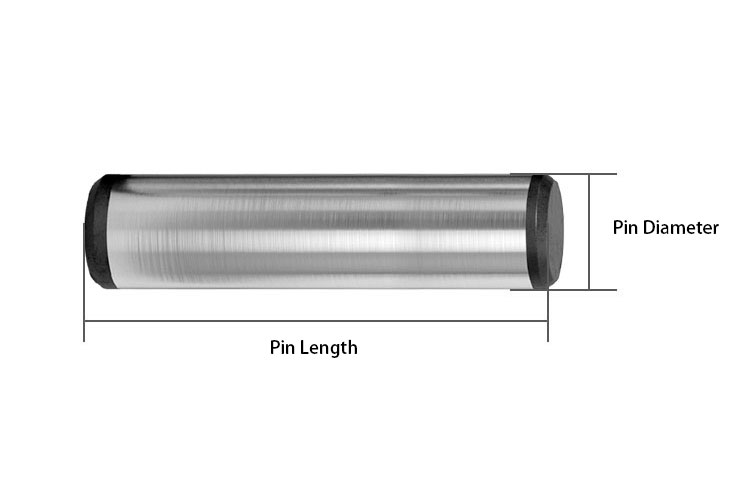

Diagram of Dowel Pins

Specifications

| Size | Φ0.8 to Φ50 (or custom). |

| Standard | DIN, ISO, JIS, PN, ASME, NF or As requested. |

| Material | Stainless steel, carbon steel, alloy steel, tool steel, brass, wood. |

| Surface treatment | White blue zinc, color zinc, oxidized black, dacromet, nickel plating, zinc plating, anodize, bead blasted, silk screen, pvd plating, chrome/titanium plating, brushing, painting, powder coated, passivation, electrophoresis, electro polishing, knurl, laser/etch/engrave etc. |

| Heat treatment | High frequency quenching, vacuum heat treatment, quenching and tempering treatment. |

| Strength | Grade 4.8, 6.8, 8.8, 10.9, 12.9 ; A2-50, A2-70, A2-80, A4-70, A4-80. |

| OEM | Supported. |

| Lead time | Sampling: 3-5 workdays Normal making: 5-10 workdays Complex design/making: 10-18 workdays |

| Fitting method | H7/s6, H7/k6, H7/m6, H7/H6, H7/G6. |

| Packaging | Plastic bag, plastic box, carton, wooden case, pallet or customized package. |

| Order process | Customer inquiries → Provide Spec./CAD/3D drawing → Engineer check and quote → Offer PI → Customer Send PO → 50% advanced payment(100% for First time cooperation) → Factory production process → QC passed → Packing and deliver at the first time → Ship to customers |

How to Choose the Dowel Pin Fitting Method?

Between the hole and the shaft:

There is relative movement (rotation or movement): clearance fit.

No relative movement: transmits large torque, cannot be disassembled → interference fit; high positioning accuracy requirements, adds keys to transmit torque, needs to be disassembled → transition fit; adds keys to transmit torque, frequently disassembled → clearance fit.

Dowel Pin Materials

- Alloy steel: Strong, high tensile strength, excellent wear resistance, fatigue resistance, and anti-galling properties.

- Stainless steel: Strong, corrosion resistant, heat resistant. SUS303, SUS304, SS316, SS316L, 17-4PH, etc.

- Surface-hardened carbon steel: Less brittle than carbon steel, does not break under high stress.

- Nylon: Lightweight, non-conductive, impact resistant, wear resistant, corrosion resistant.

- Wooden dowel pins: Available in grooved and spiral styles, suitable for furniture structure reinforcement.

- Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper.

- Titanium: GradeF1-F5.

- Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc.

- Aluminum: 2000 series, 6000 series(6061/6063), 7075, 5052, etc.

✅ Main Uses of Dowel Pins:

- Mold manufacturing: Precise alignment of upper and lower molds.

- Automotive industry: Positioning of engine blocks and cylinder heads.

- Aerospace: High-precision assembly of structural components.

- Electronic devices: Alignment of housings and internal components.

Standards

| DIN 7 | ISO 8733 | ISO 8735 | ISO 8734 | ASME/ANSI B18.8.7M | KS B1320 |

| DIN 6325 | ISO 2340 | UNI 6364A | EN 28735 | PN 85021 | UNI 1707 |

| ISO 2338 | DIN 7979 | NF E25-756 | EN 22338 | PN 85018 | JIS B 1359 |

| NF E25-751 | NF E25-753 | NF E25-757 | EN 22340 | JIS B 1355 | JIS B 1354 |

| ASME/ANSI B18.8.2 | NF E25-755 | ASME/ANSI B18.8.5M | EN 28734 |

Note: Diameter: From Ø1 mm to Ø20 mm (or custom); Length: From 3 mm to 120 mm (or custom).

Dowel Pin Types

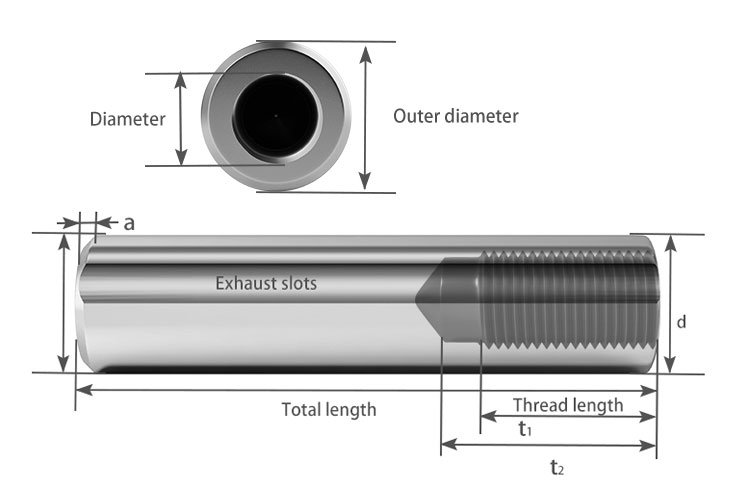

Threaded Dowel Pin

Vented pull-out threaded dowel pins have an internal threaded hole and vent holes and can be removed using a screwdriver or pull-out tool. Suitable for blind hole applications.

Standard Solid Dowel Pin

Standard round (no hole), smooth, solid, and unthreaded. For through-hole applications.

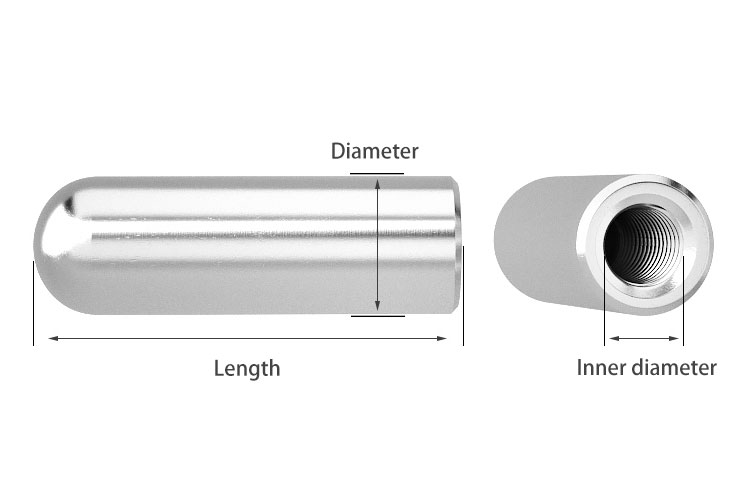

Cylindrical Pin with Round Head

The precision cylindrical pin has a spherical head on one end and an internal threaded hole on the other end. You can use a pin puller to screw into the internal threads on the end to pull it out.

Knurled Cylindrical Pin

Knurled cylindrical pins have raised teeth on the outer cylindrical surface (straight, crosshatch, or custom). The knurled teeth bite into the hole material to create a mechanical interlock.